A suggestions system refers to your closed loop system for machining Handle that consists of a number of sensors, transducers, and relays. They report and provide actual-time opinions about Resource movement, place, along with other info to your machine Manage device.

The vertical machining center typically has three linear movement coordinates. There exists also a horizontal axis rotary table attached to its worktable. This aids it to fabricate round workpieces simply.

Determined by the nature with the parameters them selves, they may be additional divided into normal parameters and parameters having a magic formula degree classification.

Its elements have sturdy styles to provide top-quality torque, horsepower, and machining speed. The level of automation of vertical milling centers also allows them to chop numerous supplies and cut down General manufacturing prices.

(three) Observe the elements with severe working disorders over the machine Software. During the processing on the NC machine Resource, coolant is commonly necessary to wash and cool the workpiece and tools at the same time.

Since we’ve covered what we like and don’t like about these CNC machines, Permit’s protect a lot of the other most vital components when buying a workshop-Prepared CNC mill.

When you search out the most beneficial CNC mill in your compact store, you'll discover that not just about every CNC machine you run into will show to get a superb in shape for your personal occupation. The very best CNC machine is calibrated for your particular purposes and capabilities.

The objective of simulation is to avoid wasting programming time, Increase the machine Instrument’s true utilization, and lessen debugging time when processing workpieces. It doesn't warranty the actual processing of elements.

The process of figuring out the Instrument’s movement route over a CNC machine Resource is referred to as interpolation. It requires including intermediate points amongst regarded details with the keep track of, determined by a specified velocity and path, and managing the workpiece table and Instrument to pass through these points.

The electrical fault prognosis of CNC machine tools entails a few stages: fault detection, fault evaluation, and fault isolation and site.

The machining center can be a highly automated multi-operate CNC machine Device Outfitted that has a Resource journal and Explore an automatic Resource improve product, which enormously improves creation efficiency and automation.

Significantly for your external auxiliary equipment: if there is a hydraulic system pump station, Test if the amount of hydraulic oil is ample; for the people with the air strain system, often drain the air compressor and gas storage tension vessel to avoid abnormal humidity from accumulating and getting into the machine tool beneath the pressure of air movement, which can lead to corrosion and damage to elements and factors.

General, this isn’t the most effective benchtop CNC mill Now we have reviewed for just a machining center, however it is a deserving contender.

It opens the chuck jaws and facilitates the disassembly of labor holding. The operator presses the change or pedal With all the foot Anytime the chuck really should begin, end, or disassemble.

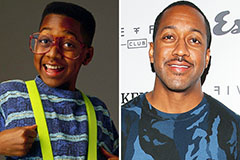

Jaleel White Then & Now!

Jaleel White Then & Now! Phoebe Cates Then & Now!

Phoebe Cates Then & Now! Melissa Sue Anderson Then & Now!

Melissa Sue Anderson Then & Now! Bo Derek Then & Now!

Bo Derek Then & Now! Kerri Strug Then & Now!

Kerri Strug Then & Now!